Toe Jack

Features

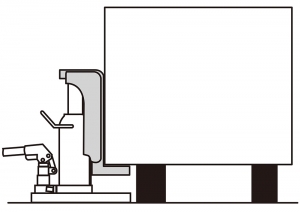

- A toe jack (also known as a floor jack) is a bottle jack attached with the toe that is designed to lift items with very low or high clearances as long as 20 mm of the gap

- Since the toe structural part has two lifting points, i.e. its toe and head points, it can be used for much wider applications than before.

- Their insertion sockets can rotate so that their operators can handle pumping at the best positions.

- They are equipped with a safety valve to prevent overload, enhancing work safety.

Four Basic Functions

-

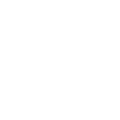

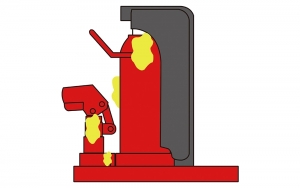

1.Lifting

It is a very basic function of it. Since both its toe and head can lift its load, its usage is twice than before.

-

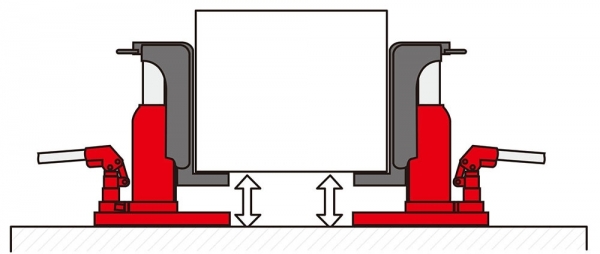

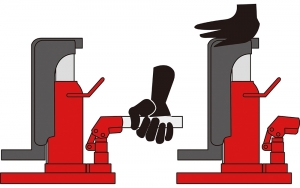

2.Adjustment of positioning

EAGLE toe jack can do position adjustment as fine as an millimeter order. It is best suited for delicate works like machines’ level matching.

-

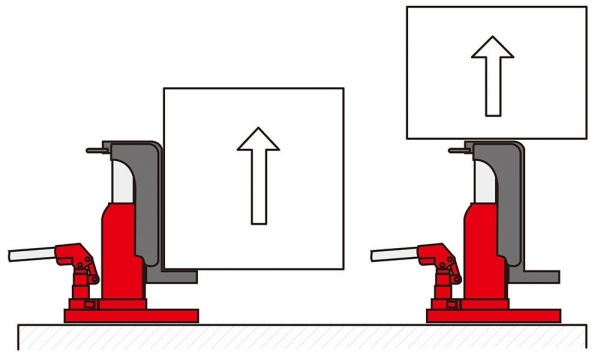

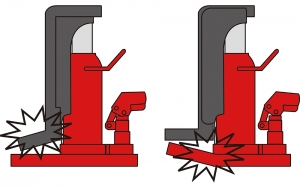

3.Widening

By placing its base on one side, and its toe on the other side, the toe-jacks can widen the gap between two objects.

-

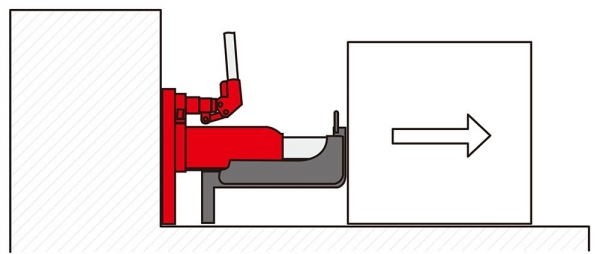

4.Lateral pressing

In case of setting a machine, you may sometimes want to slide it a little bit. EAGLE’s joe jacks can be laid down to slide the machine by using the counterforce from the wall.

Nickel-plated Type

We can also manufacture a nickel-plated type of toe-jack which are surface-treated with nickel-plate, widely used for clean-room applications, such as semiconductor equipment, electronics, chemical processing, pharmaceuticals, chip manufacturing and food processing. Since our toe jack is a nickel-plated type, paint removal type, which is safe to use under clean-room environment.

We can also manufacture a nickel-plated type of toe-jack which are surface-treated with nickel-plate, widely used for clean-room applications, such as semiconductor equipment, electronics, chemical processing, pharmaceuticals, chip manufacturing and food processing. Since our toe jack is a nickel-plated type, paint removal type, which is safe to use under clean-room environment.

* Nickel-Plated Model is [Standard Model + C] : G-100C, G-100LC

For example: Nickel-plated type of G-100 is [G-100C]

* Capabilities and specifications are the same as the standard model.

Specification

| Model | E-60 |

| Toe capacity | 3 ton |

| Head capacity | 6 ton |

| Minimum toe height | 19 mm |

| Toe length | 50 mm |

| Stroke | 113 mm |

| Body weight | 233 mm |

| Base width | 155 mm |

| Base length | 236 mm |

| Product weight | 13 kg |

| Download dimension drawing | |

| Model | E-100 |

| Toe capacity | 5 ton |

| Head capacity | 10 ton |

| Minimum toe height | 22 mm |

| Toe length | 55 mm |

| Stroke | 130 mm |

| Body weight | 288 mm |

| Base width | 183mm |

| Base length | 262 mm |

| Product weight | 21 kg |

| Download dimension drawing | |

| Model | E-200 |

| Toe capacity | 10 ton |

| Head capacity | 20 ton |

| Minimum toe height | 28 mm |

| Toe length | 60 mm |

| Stroke | 140 mm |

| Body weight | 333 mm |

| Base width | 230 mm |

| Base length | 300 mm |

| Product weight | 38 kg |

| Download dimension drawing | |

| Model | E-60L |

| Toe capacity | 3 ton |

| Head capacity | 6 ton |

| Minimum toe height | 22 mm |

| Toe length | 80 mm |

| Stroke | 115 mm |

| Body weight | 236 mm |

| Base width | 155 mm |

| Base length | 266 mm |

| Product weight | 14 kg |

| Download dimension drawing | |

| Model | E-100L |

| Toe capacity | 5 ton |

| Head capacity | 10 ton |

| Minimum toe height | 25 mm |

| Toe length | 75 mm |

| Stroke | 130 mm |

| Body weight | 291 mm |

| Base width | 183mm |

| Base length | 282 mm |

| Product weight | 21 kg |

| Download dimension drawing | |

| Model | E-200L |

| Toe capacity | 10 ton |

| Head capacity | 20 ton |

| Minimum toe height | 32 mm |

| Toe length | 80 mm |

| Stroke | 140 mm |

| Body weight | 337 mm |

| Base width | 230 mm |

| Base length | 320 mm |

| Product weight | 41 kg |

| Download dimension drawing | |

Parts List

Instruction Manual

Jacking-up operation

|

1. Connect the accessory operation levers (set of 2 parts) to one. |

|

|

2. Insert the tip of the operating lever into the release screw, rotate it clockwise, and tighten it firmly as you tighten the screw. |

|

|

3. Operate the pump by inserting the operation lever into the lever socket and moving it up and down. The toe (ram) rises to jack up heavy objects. |

|

|

4. After raising it to the desired position, pull out the operation lever from the lever socket so that the operator will not trip over it. |

|

Lowering-down operation

|

1. Insert the tip of the operating lever into the release screw and loosely rotate the screw to the left (counterclockwise) to open the release circuit and lower the toe (ram). |

|

|

2. The ram will automatically lower down due to the applied load |

Operating manual

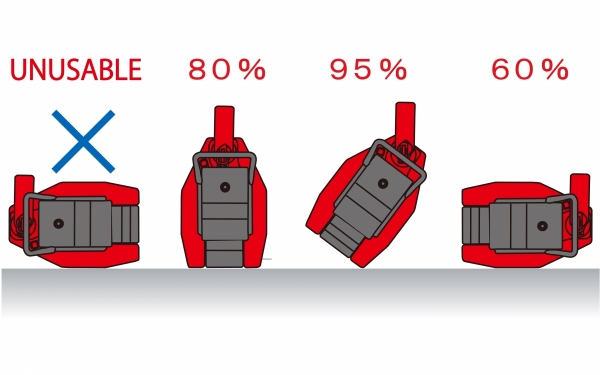

Laid Down For Using

The following toe jack can be laid down for using.

- G-60

- G-100

- G-60L

- G-100L

The operating power does not change even when used sideways, but the stroke varies depending on the toe jack usage angle

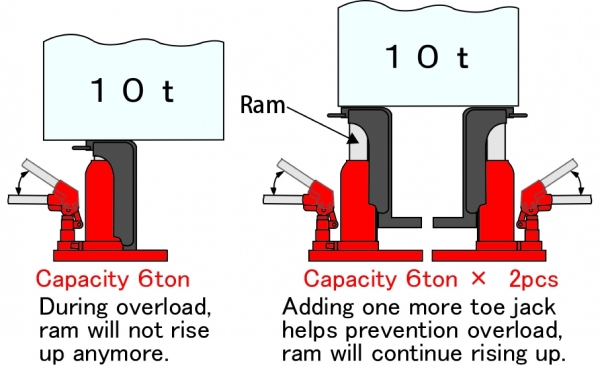

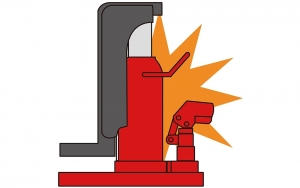

Safety Valve

- The safety valve will be operated when weight of the load is beyond its capability. The ram does not go up while the safety valve is operating.

- The ram does not go up even in the process of jack operation when it is beyond its capability. In this case, ram will not go down, will remain at that position.

- The pressure of the safety valve is set depending on the head capacity. The safety valve is not equipped to avoid of toe & base bending but for the purpose of protecting the jack itself.

- The jack can go up again after the overload is cleared.

Safety Precautions

- In the process of jack operation, never expose any part of your body under the heavy object being handled. Falling or rollover the heavy object may lead to serious injuries or even fatalities

- When it is required to hold the heavy object at an elevated position after jacking up, be sure to use proper means (trestles, sleepers, blocks, etc.) under it for safe and stable support. Supporting with toe jack alone are precautious, and may lead to falling or rollover hazards which may lead to injuries

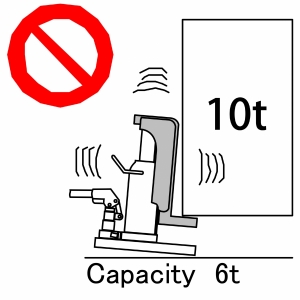

- Never use jack which is over its specifications. Jack may yield under the overloads, toppling the heavy object, which may lead to injuries or deaths

- Operate the jack on a hard, level foundation in a stable manner. Never use the jacks on a slope or soft ground. The load may fall off or overturn.

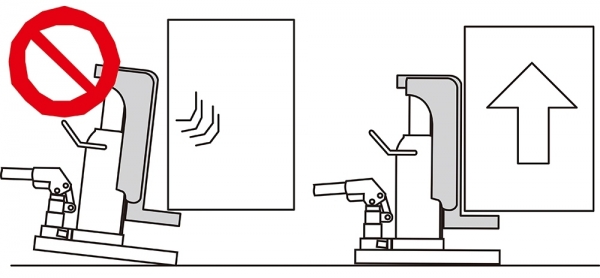

- Be sure to engage the toe fulling under the heavy object to be lifted. Supporting the load only by the force-end of the toe is dangerous, the load may slip off or even a slight fall of the jack may cause a falling or rollover accident.

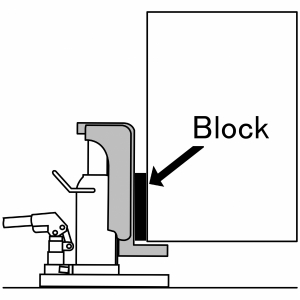

- If a clearance is developed between the load and the leg of the toe, be sure to insert a block at a proper size in between in order to prevent dangerous fall of the jack.

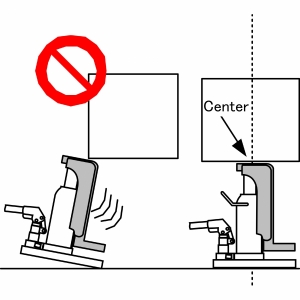

- When supporting a load on the ram head, be sure to support the load at the center of the ram head (head bolt position). If the load is off center, the jack may fall over and the load may fall of or overturn.

Daily Checklists

Before operation

Check the list below before operation. If there is any following problems, do not use the jack and take action such as repair, etc.

- Oil leak

- The toe jack cannot move up and down smoothly without the load

- Deformation or distortion of the toe or base

- Any other problems

After operation

- Down to the bottom and set the release screw loosely before storing it

- Wipe the dirt, sand, and other stain, off the pump before storing it

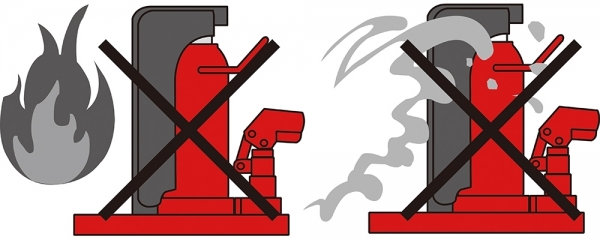

- Keep away from fire, water and marine water

- Any other problems during or after operations, do not store the jack as it is, take action such as repair, etc