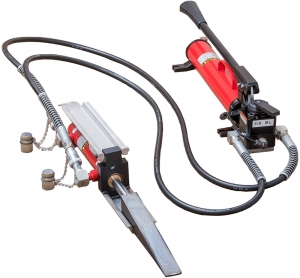

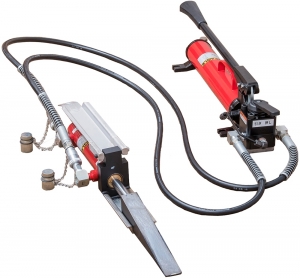

Power Wedge

Power Wedge is a tool for aligning in 1 mm units while pushing the machine when setting the industrial machine.

Power Wedge is a tool for aligning in 1 mm units while pushing the machine when setting the industrial machine.

It can be used without receiving reaction force.

Feature

- The power wedge is a tool for pushing the machine and aligning it in units of 1 mm when installing the machine.

- Unlike the conventional bar, power wedge can be pushed horizontally without damaging the floor.

- The reaction force is not required, so the efficiency of side pushing work is improved.

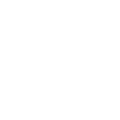

SAFE and SMART pushing operation now becomes possible

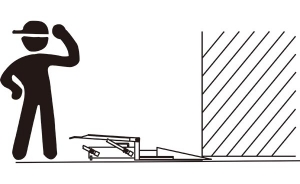

Positioning with bar will hurt the floor and it will be difficult to get a perfect fit.

Positioning with bar will hurt the floor and it will be difficult to get a perfect fit.

However, with the Power Wedge, there are no worries about damaging the floor, and make fine adjustments in 1 mm increments by operating the handle. Also, using of the bar to push is dangerous because it may recoil and the body may be blown off. However, since the power wedge is operated by an external pump, operators can operate them remotely, and it is so safe.

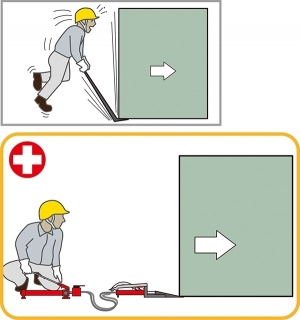

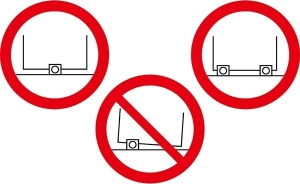

Pushing sideways without receiving reaction force

In order to push the machine sideways with a standard toe jack, etc., it is necessary to receive a reaction force on the wall. In addition, you will need square timber to fill the gap between the jack and the machine. However, since the power wedge can carry out lateral pushing work without receiving reaction force, the efficiency of lateral pushing work is improved.

In order to push the machine sideways with a standard toe jack, etc., it is necessary to receive a reaction force on the wall. In addition, you will need square timber to fill the gap between the jack and the machine. However, since the power wedge can carry out lateral pushing work without receiving reaction force, the efficiency of lateral pushing work is improved.

Specification

| Model | KP-15 |

| Capacity | 15 ton |

| Minimum toe height | 6 mm |

| Maximum toe height | 34 mm |

| Toe length | 40 mm |

| Toe width | 43 mm |

| Wedge length | 629 mm |

| Wedge height | 128 mm |

| Body width | 70.5 mm |

| Cylinder stroke | 150 mm |

| Oil required | 114 cc |

| Set weight |

30 kg |

| Download dimension drawing KPS-15 | |

| Model | KP-35 |

| Capacity | 30 ton |

| Minimum toe height | 6 mm |

| Maximum toe height | 34 mm |

| Toe length | 40 mm |

| Toe width | 53 mm |

| Wedge length | 677 mm |

| Wedge height | 137 mm |

| Body width | 87 mm |

| Cylinder stroke | 150 mm |

| Oil required | 208 cc |

| Set weight | 35 kg |

| Download dimension drawing KPS-35 | |

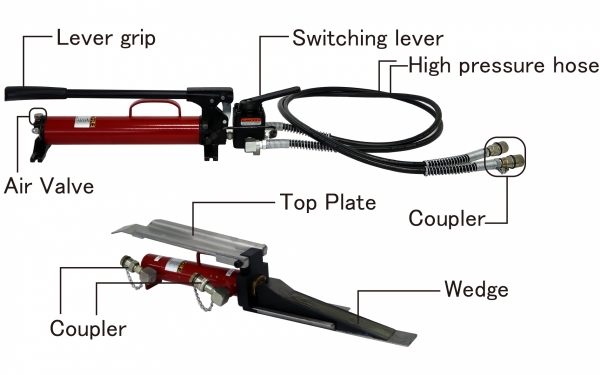

Parts List

Operation manual

Before work

|

1. Securely connect the high pressure hose and power wedge with coupler |

|

|

2. Turn the air valve counterclockwise to open. |

|

Pushing work

|

1. Raise the upper plate and insert the wedge directly under the heavy object. |

|

|

2. Turn the manual pump switching lever to the “PUSH” side. |

|

|

3. By moving the handle up and down, the wedge moves forward with hydraulic force and pushes the heavy object forward. |

|

After work

|

1. Turn the switching lever of the manual pump to the “PULL” side and move the handle up and down to shorten the wedge to the minimum length. |

|

|

2. Return the switch lever to neutral |

|

|

3. Turn the air valve clockwise to close it. |

|

|

4. After confirming that the wedge has been shortened to the beginning, remove the high pressure hose from the jack. Be sure to attach the duster cap to the coupler. |

|

Precautions

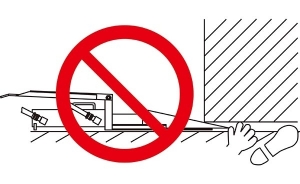

- During the work process, never put a part of your body such as hands or feet or the whole body under a heavy object. There is a risk of death or serious injury due to accidents such as dropping or overturning heavy objects.

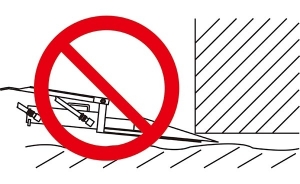

- Do not use on sloped or soft ground.

- Install the pump in a horizontal and safe place. A safe place is one that is flat and solid with no obstacles around it.

- Do not use the power wedge as a lever.

- Make sure there are no workers directly behind the power wedge body before starting work. This does not mean that they will be able to retreat.

- Set the power wedge so that it does not hang while looking at the balance of heavy objects etc.

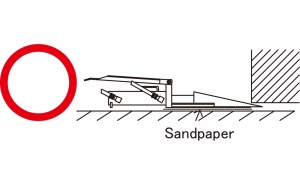

- When pushing sideways, make sure that the opposite side of the power wedge is slippery. For safety, please lay sandpaper etc. under the power wedge body lower plate.

- Never run off the grease on the wedge part. Also, before use, check that the wedges are free of dust and dirt. If adhered, wipe off with a waste cloth and reapply grease.

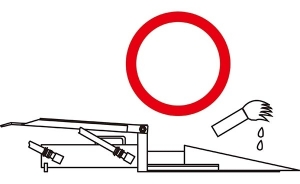

- Air is required in the oil tank of the manual pump. Be sure to follow the level gauge when refueling the oil tank. If the tank is filled with oil, a vacuum will be generated in the tank and the oil will not be discharged.

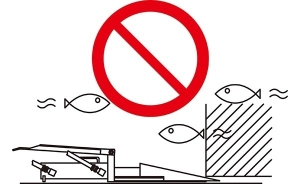

- Do not use in water, sea or muddy water.

- The manual pump is for power wedge only, do not use it with other jacks.

- When removing the coupler, set the wedge part back to the root and set the manual pump switching lever to the neutral position (release the pressure) before removing it.

- Before removing the coupler, set the wedge part back to the root and set the manual pump switching lever to the neutral position (release the pressure) before removing it.

Daily checklist

Before use

Check the following items before use, and if applicable, take measures such as sending the power wedge for repair without using it.

- When the upper plate, lower plate and wedges are damaged or bent.

- If the hose or coupler is scratched or damaged.

- When the movement is not smooth due to expansion and contraction to the stroke end with no load.

- When it does not extend to the stroke end with no load.

→Please add oil to the pump - When the movement of the wedge is unstable when used with no load.

→Apply grease to the top and bottom of the wedge. - When other abnormalities are found

After use

- After use, keep the following items and store it indoors at room temperature.

- Return the power wedge to the minimum length, attach the duster cap to the coupler, and lightly tighten the air valve of the pump before storing.

- If there is mud, sand, or other deposits on the power wedge/manual pump parts, clean them and store them.

- Do not store in the vicinity of fire or where it may be exposed to water or seawater.

- If any deformation, damage, oil leak or other abnormality is found during or after use, take measures such as sending it out for repair without storing it.