Toe Jack With Slide Table

It is a kind of toe jack that allows fine adjustment of front, back, left and right with a heavy object placed on the toe, widely used for assembling during installation of heavy machineries such as printing machines and semiconductor manufacturing equipment.

It is a kind of toe jack that allows fine adjustment of front, back, left and right with a heavy object placed on the toe, widely used for assembling during installation of heavy machineries such as printing machines and semiconductor manufacturing equipment.

Toe Jack With Slide Table

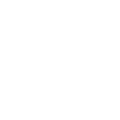

- It enables forward/backward position adjustment while keeping heavy load in a jacked position.

- It is assembled individually to slide table consisting of ball bearings.

- It enables fine position adjustment of forward/backward and up/down within the range of 100mm.

※Cannot load on the head of the jack

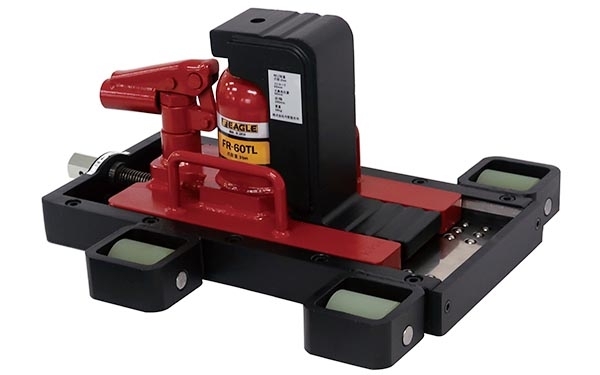

Slide Table with Roller

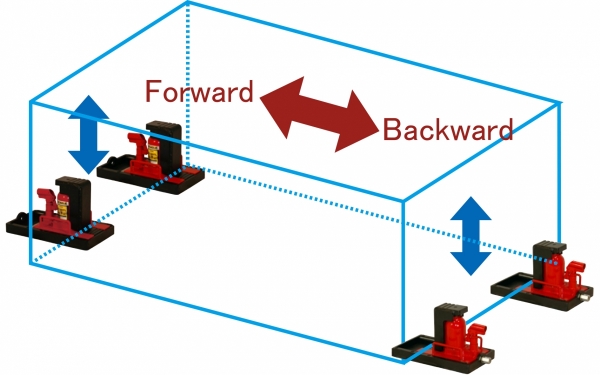

- It enables forward/backward, up and down, left and right position adjustment while keeping heavy load in a jacked position.

- This model consists of an F-series jack and wheels that are made of urethane, enabling fine position adjustment in three directions, forward/backward, left/right and up/down while keeping the load in a jacked position.

- It enables fine position adjustment of forward/backward, up/down and left/right within the range of 100mm.

※Please use a set of 3 or more to ensure safety operation

※Can not load on the head of the jack

※Please do not move heavy objects over 100 mm

-

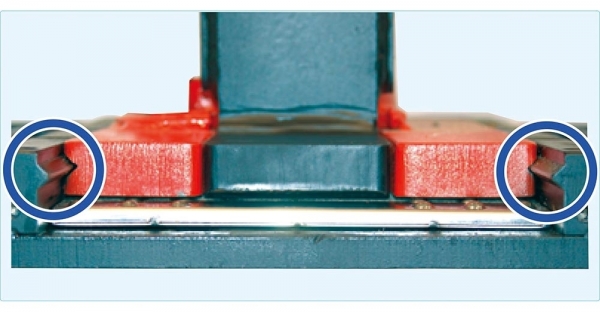

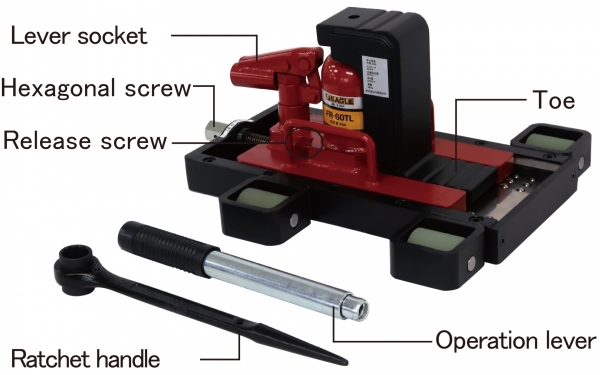

Ant Ditch Guide

For the toe jack with slide table, the base and jack are integrated by the ant ditch guide on the side of the jack base.

-

Efficient fine adjustment

The lever handle allows fine adjustment up and down, and the ratchet handle allows fine adjustment forward and backward.

Nickel-plated Type

We can also manufacture a nickel-plated type of toe-jack with slide table which are surface-treated with nickel-plate which is used for clean-room applications, such as semiconductor equipment, assembly, electronics, chemical processing, pharmaceuticals, chip manufacturing and food processing. Since our toe jack is a nickel-plated type, paint removal type, which is safe to use under clean-room environment.

We can also manufacture a nickel-plated type of toe-jack with slide table which are surface-treated with nickel-plate which is used for clean-room applications, such as semiconductor equipment, assembly, electronics, chemical processing, pharmaceuticals, chip manufacturing and food processing. Since our toe jack is a nickel-plated type, paint removal type, which is safe to use under clean-room environment.

* Nickel-Plated Model is [Standard Model + C] : F-60TLC, F-100TLC

For example: Nickel – Plated Type of F-60TL is [F-60TLC]

* Capabilities and specifications are the same as the standard model.

Specification

| Model | F-60TL (Slide table) |

| Toe capacity | 3 ton |

| Head capacity | Unusable |

| Stroke | 62 mm |

| Slide width | 100 mm |

| Minimum toe height | 41 mm |

| Toe length | 80 mm |

| Toe width | 65 mm |

| Base length | 422 mm |

| Base width | 202 mm |

| Body height | 202 mm |

| Product weight | 25 kg |

| Download the dimension drawing | |

| Model | F-100TL (Slide type) |

| Toe capacity | 5 ton |

| Head capacity | Unusable |

| Stroke | 63 mm |

| Slide width | 100 mm |

| Minimum toe height | 44 mm |

| Toe length | 75 mm |

| Toe width | 75 mm |

| Base length | 443 mm |

| Base width | 223 mm |

| Body height | 243 mm |

| Product weight | 32 kg |

| Download the dimension drawing | |

| Model | FR-60TL (Roller type) |

| Toe capacity | 3 ton |

| Head capacity | Unusable |

| Stroke | 62 mm |

| Slide width | 100 mm |

| Minimum toe height | 50 mm |

| Toe length | 80 mm |

| Toe width | 65 mm |

| Base length | 422 mm |

| Base width | 345 mm |

| Body height | 211 mm |

| Product weight | 28 kg |

| Download the dimension drawing | |

| Model | FR-100TL (Roller type) |

| Toe capacity | 5 ton |

| Head capacity | Unusable |

| Stroke | 63 mm |

| Slide width | 100 mm |

| Minimum toe height | 53 mm |

| Toe length | 75 mm |

| Toe width | 75 mm |

| Base length | 443 mm |

| Base width | 375 mm |

| Body height | 252 mm |

| Product weight | 39 kg |

| Download the dimension drawing | |

Parts List

Instruction manual

Lifting up operation

|

1. Connect the operation levers (set of 2) to one. |

|

|

2. Insert the operation lever into the release screw, rotate it clockwise, and tighten it firmly |

|

|

3. After lifting up the desired position, pull out the operation lever from the lever socket so that the operator will not trip over it. |

|

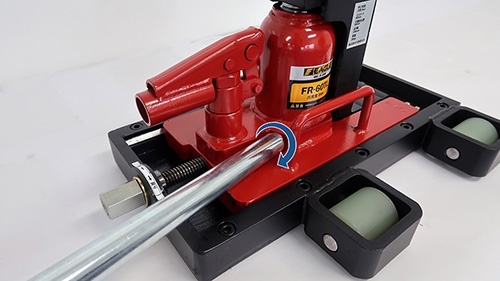

Adjustment of position of heavy load

|

1. Insert the attached ratchet handle into the hexagonal screw at the rear of the jack and perform ratchet operation to move the jack part back and forth. |

|

Lowering operation

|

1. Insert the tip of the operating lever into the release screw and loosely rotate the screw to the left (counterclockwise) to open the release circuit and lower the head (ram). * Be careful not to loosen the release screw more than 2 turns. * When lowering, hold the handle with both hands and operate it carefully. |

|

|

2. The ram returns due to the applied load. |

Operating Manual

Precautions

- When lifting up heavy machinery, pay attention to the items described in the precautions on the toe jack’s page (Toe Jack’s Safety Precautions) and set it properly.

- For the toe jack with slide table, only the toe part can be used. Never put the machine on the toe head. There is a risk of falling and overturning machine.

- Be sure to use the accessories for the lever and ratchet handle.

- Do not move heavy objects more than 100 mm with the toe jack with a slide table

- Do not remove the jack body from the slide table.

Daily checklist

Before use

Before use, check the following items, and if applicable, take measures such as sending them out for repair without using the toe jack with slide table

- When there is any oil leakage on the jack.

- When operation is not smooth when raising/lowering to the stroke end with no load.

- When distorted at any parts of the toe/base/slide table.

- When other abnormalities are found.

After use

After use, keep the following items and store it indoors at room temperature.

- Lower the toe part to the bottom and lightly tighten the release screw before storing.

- If there is mud, sand, or other dusts on each part of the jack, clean it and store it.

- Do not store near fire or in places where it may be exposed to water or seawater.

- If any deformation, damage, oil leak, or other abnormality is found during or after use, take measures such as sending it for repair without storing it.