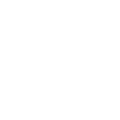

Lifting Jack

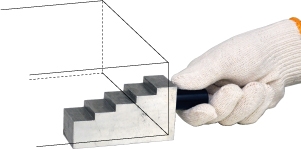

Lifting Jack is one type of jack enables vertical lifting or lowering heavy items from an access of only 9.5mm

Lifting Jack is one type of jack enables vertical lifting or lowering heavy items from an access of only 9.5mm

Features

- From the limited insertion space, Lifting Jack can lift maximum 15 ton of heavy machinery up to 37.5 mm

- Lifting Jack is excellent tool for aligning, balancing, or positioning fixed equipment

- Thanks to the light weight of 10 kg, it is easy to carry out and get the job done safely, with improved productivity

- Exclusive case makes it much easier to carry and manage the accessories

Two safety blocks included

Two safety blocks included in the Lifting Jack set, which help secure the load safely while lifting up or the lowering the load.

Two safety blocks included in the Lifting Jack set, which help secure the load safely while lifting up or the lowering the load.

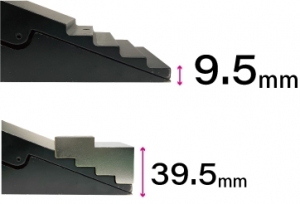

Step Block eliminates stroke’s waste

When lifting up the load, pumping operation sometimes takes time to reach the load. Lifting Jack equipped with each step block which are able to eliminate the stroke. The work efficiency increase more than ever.

When lifting up the load, pumping operation sometimes takes time to reach the load. Lifting Jack equipped with each step block which are able to eliminate the stroke. The work efficiency increase more than ever.

Exclusive case included

Exclusive case makes it easier to manage accessories and to carry to the workplace.

Exclusive case makes it easier to manage accessories and to carry to the workplace.

Specification

| Model | LJ-150 |

| Capacity | 15 ton |

| Minimum height | 9.5 mm |

| Maximum stroke | 58 mm |

| Body length | 536 mm |

| Gross weight | 10 kg |

| Download dimension drawing | |

Parts List

Instruction Manual

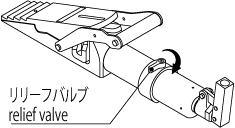

When lifting up the heavy load

|

|

|

2. Push the lever grip from the top with your hand to remove the lever hook. |

|

|

3. The “Step Block” enables the Lifting Jack to be used to lift an item with larger gap, and will lift the item further with less penetration. ①Attach the step block to the tool using the attached screw. ②Insert the entire step block under the item to be lifted. |

|

When keeping the heavy load

|

Once the item has been lifted to the desired height, or to the maximum height on the step used, the safety block should be inserted into the gap, and will keep the item safely. |

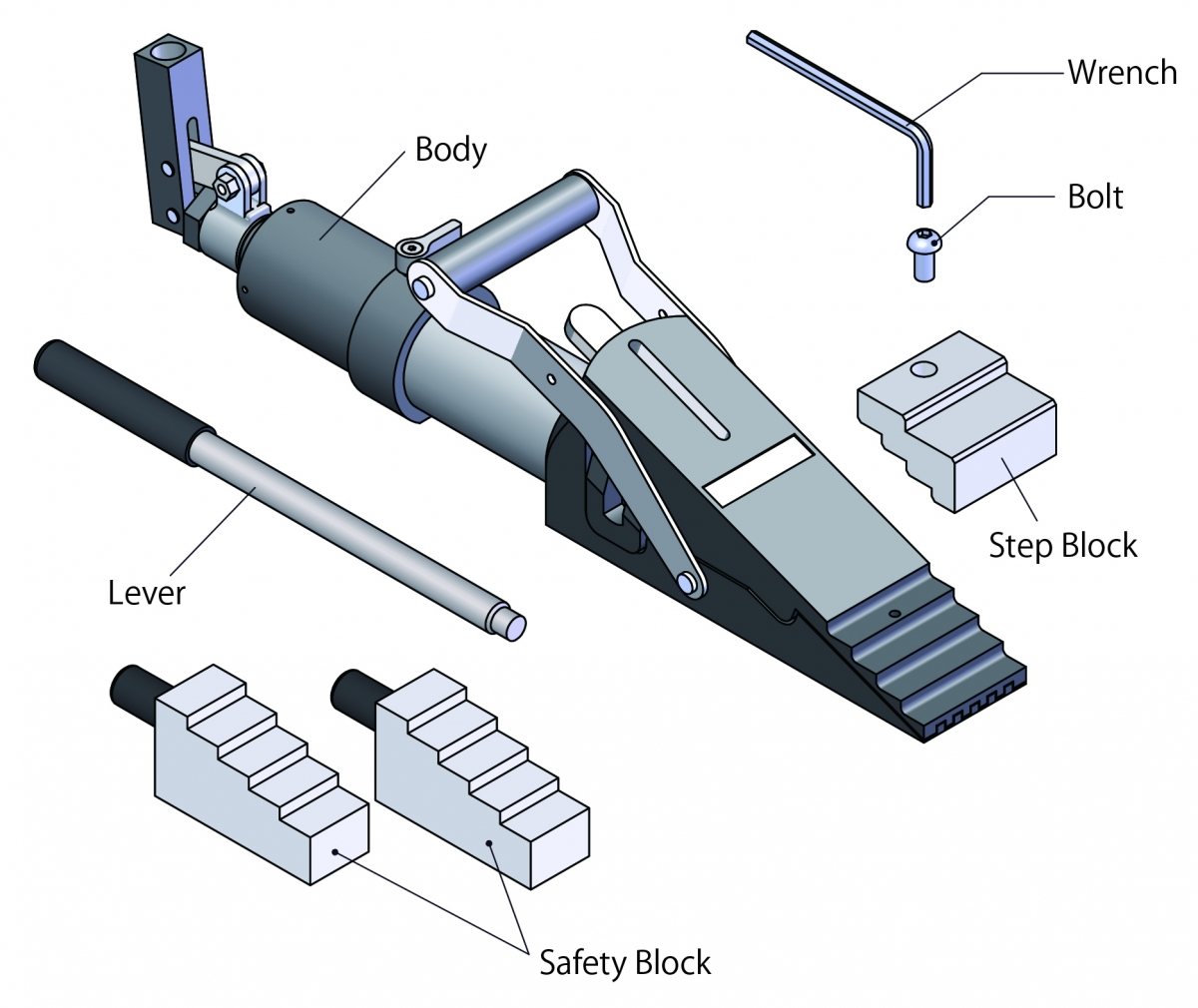

When lowering the heavy load

|

Engage the accessory lever into the eye of the release screw, and turn counterclockwise slowly. The release valve will be opened to let the wedge (and step) fall. ※Never loosen the release screw completely in a breath as the step (wedge) may drop all of a sudden to overturn the heavy object, causing a serious accident. |

Operating Manual

Safety Precautions

-

If working oil gets into eyes, rinse them off with fresh water at least for 15 minutes, then see a doctor promptly. if oil remains on your skin, wash it off with using water and soap.

-

To release the jack, turn the release screw counterclockwise carefully little by little. Never loosen the release screw completely in a breath as the step may drop all of a sudden to overturn the heavy object, causing a serious accident.

-

Use the lever furnished as a standard accessory. Never use any other lever made longer e.g. by adding an extension. The jack may be overloaded and damaged to endanger the jacking job.

-

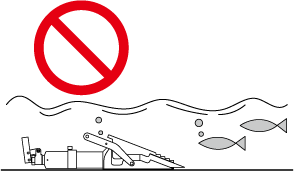

Never use the jack in the water, mud or sand. It will be damaged.

-

Use the jack within the ambient temperature range of –10℃ to +55℃. In a colder environment, the oil will be frozen up, and the packing hardened. In a hotter environment, the oil and packing will expand. In either case, the jack will not work as designed and/or get damaged.

- Remove the lever when the jack is not in use.

-

Do not remove the seal on the jack or smudge it with paint.

- Use at 70 to 80% capacity of the maximum output in each jack

-

As a general rule, hydraulic oil should be changed once a year.

-

Use ISO VG32 hydraulic working oil only.

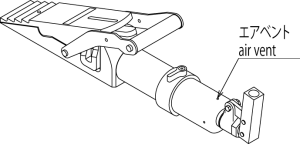

- Do not fill air vent with something tape

Daily Checklists

Before using

Check listing below before operation. If there is any following problem, do not use the jack and take action such as repair, etc

- Oil leak

- Can not run up-and-down movement smoothly without load

- Deformation or Distortion of Wedge/Step or foundation

- Any other problems

After using

After operation, please store it at room temperature according as follows;

- Store the remote toe jack after its ram is returned to the bottom.

- On return from each job and before allocation against subsequent work the completeness of the Lifting Jack kit must be established and items examined to ensure that they are serviceable.

- Down to the bottom and set the release screw loosely before store it.

- Wipe the dirt; sand, mud and other stain, off the pump before store it.

- Keep away from fire, water and marine water

- If you find any problem during/after operation, do not store the jack as-is and take action such as repair, etc.